Production Flow Chart of Fiberglass Needled Mat

Glass fiber cotton, also known as a fiberglass needle-punched blanket, is produced using alkali-free glass fiber as its primary raw material. Its main components consist of environmentally friendly inorganic materials, primarily silicon dioxide and alumina. This product is crafted from fine E-shaped glass fibers through a specialized needle-punching process, resulting in a structure filled with numerous voids. This unique construction provides excellent heat insulation, sound absorption, shock absorption, corrosion resistance, high-temperature resistance, and flame retardance.

Applications:

Glass fiber cotton is widely utilized across various industries, including household appliances, mechanical and electrical equipment, the chemical industry, construction, and automotive sectors. It serves as an interlayer dielectric and provides heat preservation, sound attenuation, insulation, and corrosion resistance.

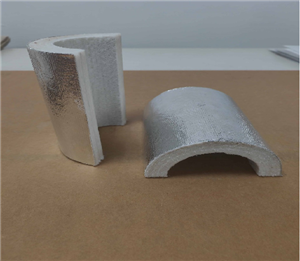

In response to customer requirements, fiberglass can be die-cut into insulation mats for slow cookers, electric cookers, microwaves, water heaters, ovens, grills, and heat-resistant pads for mosquito coil stands.

Through a specialized technical process, the fiberglass mat is transformed into a product that is non-itchy, smokeless, and free of residues, making it the ideal heat insulation sheet for food machines such as slow cookers, electric cookers, microwaves, water heaters, ovens, and grills.

Month production capacity: 300tons