Glassfiber Needled Mat Corrosion Resistance Up To 550

- PETERSBURG

- Chinese mainland

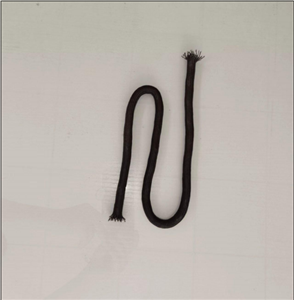

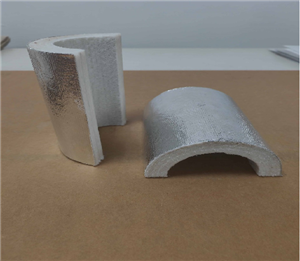

According to customer requirements die cutting, the fiberglass needle become insulation mat of slow cooker, electric cooker, micro oven, water heater, oven, grill, heat resistance pat of mosquito coil stand

We can sell you fiberglass needle mat by roll, or die-cut into your customized size or shape.

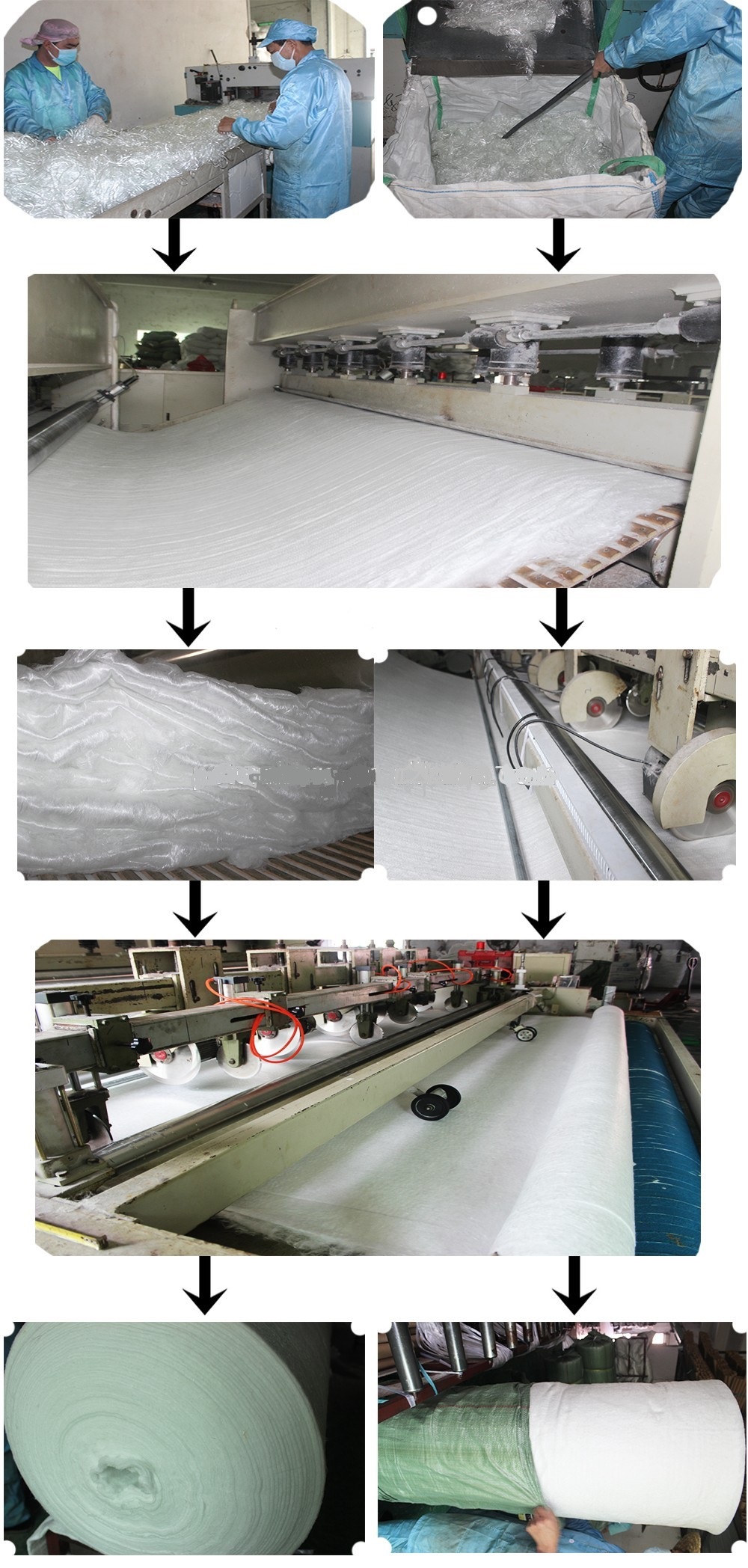

Product Introduction of fiberglass needle mat

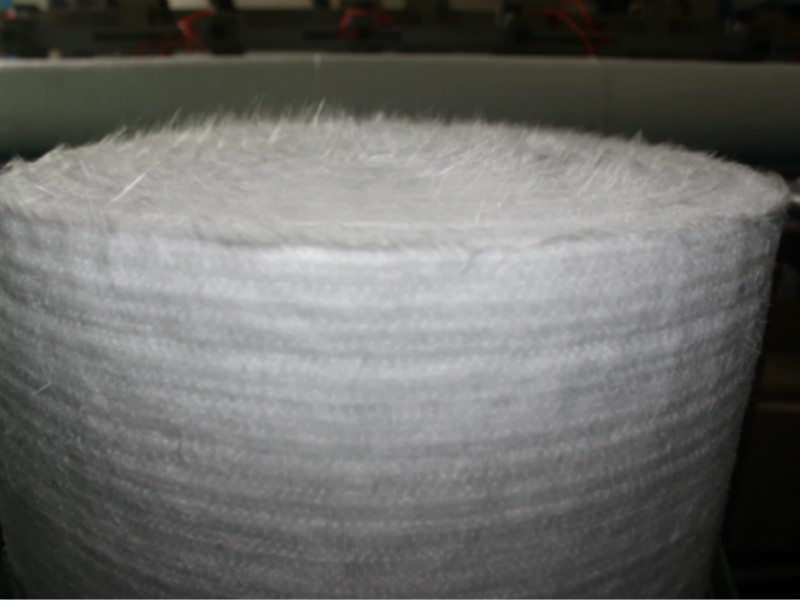

Glass fiber cotton is called fiberglass needle-punched blanket. It uses alkali free glass fiber as raw material. Its main composition is an environmental protection inorganic material composed of silicon dioxide and alumina. This product is made of exiguity E-shaped glass fibers by special needle-punching processing. Make its interior construct of numerous void pores, thus endows this product with good heat insulation, sound absorption, shock absorption and corrosion resistance, high temperature resistance, flame retardance...etc performance

Application of fiberglass needle mat

Widely used in household appliances, mechanical and electrical equipment, chemical industry, construction industry, automotive industry and other industries as interlayer dielectric, heat preservation, sound attenuating, insulation, corrosion resistance…etc.

Product size customized is available.

Performance Parameters of fiberglass needle mat

composition of glass fiber:

silicon dioxide: 52%~56%

Calcium oxide: 16%~25%

Aluminium oxide: 12~16%

Organic content: 0.9%

Thermal conductivity coefficient: 0.02-----0.036w/(m.k)

Temperature resistance:710℃ (instantaneous maximum operating temperature),

550℃ (long-term operating temperature)

Thickness: 3mm to 3cm

Width: 600mm to 2000mm

Production capacity: 500ton/month

We can sell you by roll, or die-cut into your customized size or shape