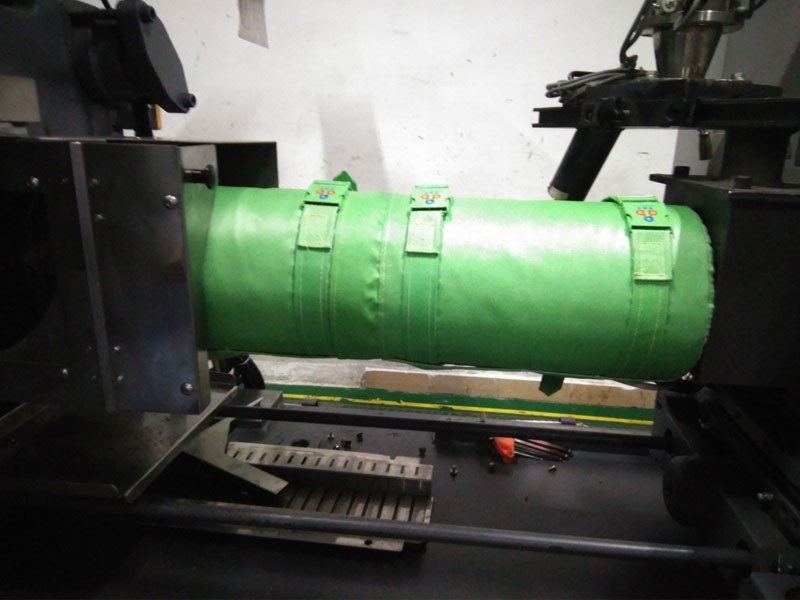

Insulation Blanket For Extruder Surface Temp Lower To 40℃

- Customized, PETERSBURG

- Chinese mainland

The Insulation blanket for extruder & barrel heater can

1. Improve the quality of plastic products due to stable temperature

2. Short return on investment period (with 20% energy-saving rate, it takes 4 to 5 months to recover the cost.

3. Less heat loss to environment and make workplace more confortable

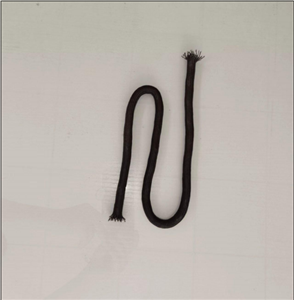

4. Easy to install & uninstall by buckles, by velcro tap...

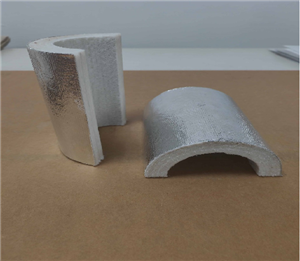

Features of the insulation blanket

①. Good insulation effect, reduce energy consumption and cooling the on-site working temperature environment

②. fire retardant, resistance to high temperature, the raw material resistant to high temperature of 550 ℃ to 1200 ℃.

③. The inner layer has good insulation and does not conduct electricity, so it is not necessary to change the circuit line of the machine during installation.

④. Acid and alkali resistance, insect bite control, mildew resistance, long service life and low maintenance cost.

⑤. The surface is oil-proof and waterproof, and easy to clean.

⑥. The energy-saving effect is generally 20-55%, depending on the requirements of customers and the use of environment.

Installation and maintenance of the insulation blanket

①. When install and disassemble the product, it should according to the opening direction of the product. And use uniform force along, not rough operation.

②. do not touch with hooks. In case puncturing the product.

③. The product shall be properly kept and stored after disassembly. Avoid impregnation.